Net zero in construction is a major focus globally at present. There is a growing body of research relating to the exploration of carbon in buildings and how to address ambitious carbon reduction targets. In this post we shall explore the carbon journey for mass timber construction and look at the various ways carbon accounting can support better outcomes for sustainable construction projects for now and into the future.

The primary ingredients that constitute mass timber construction products is timber or wood. Timber, or wood, is engineered by nature. All of the natural processes apply to the growing trees (in nature) are attributed to the primary materials for mass timber construction products, such as Glue Laminated Timber (GLT), Cross Laminated Timber (CLT) and associated products like Laminated Veneer Lumber (LVL) and Structural Timber Framing (STF).

Timber used by reputable companies in the manufacture of these products, under the umbrella of mass timber construction systems/solutions, are sourced from responsibly managed and harvested plantation tress, which as they grow sequester carbon and store it in the board of panels.

Moreover, transforming the panels from a responsibly harvested plantation resource into various products requires a manufacturing process and included in this is carbon production, commonly called embodied carbon.

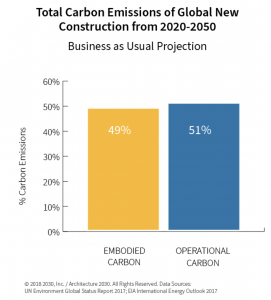

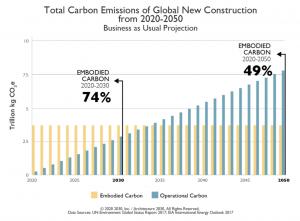

Embodied carbon is associated with materials and construction processes throughout the whole lifecycle of a building or infrastructure and differs to operational carbon — the carbon that comes from energy used to heat, cool, illuminate etc. the building during use.

As you can see from the above graphic, embodied carbon (used in production of building materials) is about 50% of all carbon produced, this is why so many developers are looking for lower embodied carbon construction solutions, like mass timber.

Of the embodied carbon impacts, it is estimated that 80% are attributed to building structures (superstructures) and enclosures using steel, concrete, masonry etc.

Of the embodied carbon impacts, it is estimated that 80% are attributed to building structures (superstructures) and enclosures using steel, concrete, masonry etc.

Once buildings are constructed they can be transformed at the ned of their usable life. Mass timber building superstructures can be dismantled (largely in a non-destructive way) with relative easy and the unfastening of connection systems. Thus making the entire building, or part of, reusable. Yep, recycle the entire superstructure and start a fresh in a new location – a concept known as cradle to cradle.

In summary, there are three levels of carbon accounting for mass timber constructed buildings, 1. Sequestered carbon, 2. Embodied carbon (in production/construction) and 3. life-course carbon, the daisy chain effects of carbon being stored throughout multiple building lives.

The inclusion of the sequestered carbon makes mass timber carbon accounting relatively unique when compared to more traditional building materials. As such, it requires a different approach – or an augmentation or attribution – within a more common tool/standard or scheme fro carbon accounting in construction.

if you are interested in supporting our journey down the new zero and carbon accounting pathway, why not lend a hand or join as a member? Your contribution either way will support our global future.

Paul Kremer Founder IAMTC.org